Erik Frost – Data unknown, my guess 1900-1920

Frost-Erik Ersson (or Frost Erik Eriksson) was born in 1865-07-29 in the village of Östnor in a family of farmers. https://www.morahembygd.se/wp-content/stigsson/pee9624ac.html

In his childhood, he suffered child paralysis, his entire upper body and arms were attacked.

In 1887-06-07, Frost emigrated to the USA, like many others from his generation, to work as a lumberjack where we became known as Erik Frost.

In 1890, Frost returned home and later in the year married Smids Anna Andersdotter (seven months before the first child Kristina was born) https://www.morahembygd.se/wp-content/stigsson/p786244cf.html. In total, they will have 8 children.

1891 also mark the year when he opened the sled and carriages factory called Erik Frost. See here a video of examples of similar style carriages https://www.youtube.com/watch?v=Qvfw-QxuP50

Mentioned in the 120 Morakniv book “. According to Karl Erik Forslund’s book, Med Dalälven from källorna, “Erik Frost started making carriages in 1891 and knives in 1898, that were sold in many countries”.

Although producing the sleds and carriages was the main business, in the next few years, the company started also to sell other things, many times referred to more as a trading house where various activities took place. He now sells knives and knife components (that were initially made just for internal usage in the factory workshop), woodworking tools, Kerosene, food, shirts, and underpants, etc.

At the time, knives were only tools made internally for workshop usage. According to the article from 1944-12-04 Falu-Kuriren newspaper, Skeri Erik Aronsson (probably https://www.geni.com/people/Skeri-Erik-Aronsson/6000000015157284218 ) was the first smith in the factory. He joined Erik Frost in the autumn of 1891 and was alone for some time. It's unclear if Erik Frost already knew how to forge or was Skeri Erik Aronsson the first knife maker that started it all.

Still according to the article “1944-12-04 Falu-Kuriren”, the first major upgrade from manual work to industrialization, was the acquisition of a kerosene engine to power a spring hammer, followed by a lathe to turn the handles.

Invoice from 1897. On the top of the invoice is written “Manufacturing and selling winter carriages e.g. sleds larger and smaller made from the best material at lowest price” “Manufacturing and selling four-wheel wagons e.g. carriages made from the best material at lowest price Fast deliveries”. The invoice itself is for an assorted of materials, Hinges, studs, hooks, etc

In this invoice from 1903 already appears the advertisement to the Mora knives in 3 sizes, among all the other things he made and sold, carriages, sleds, cotters, etc. The invoice is for a repair of shakes for horse-drawn carriages and the shrinking of the steel rim on a wooden wheel.

However, evidence in the bookings, indicates that knife production picked up as early as 1894 and in 1898 was the first batch of knives was exported. Frost’s wood carving tools and sheath knives were sold to different types of customers like wholesalers, gunpowder traders, etc all over Sweden.

One of the major first clients was Ting-ströms AB I Göteborg, which still at least until the 1990s maintained as a satisfied customer. Ref: 1991-02-12 Dala-Demokraten

Above: paper records found at E Jönsson workshop belonging to Jöns Persson from Fev 1900 with a reference to Erik Frost

More info about Jöns Persson here https://oldmora.blogspot.com/2020/06/katrin-jons-persson.html and E Jönsson factory, here https://oldmora.blogspot.com/2019/11/e-jonsson-broderna-jonsson-1936.html

In the earlier 1900s, both internal and external markets show great interest in the knives, that were marketed as having superior sharpness and resilience because of the laminated steel (hardened steel core and soft steel outer layers.

Erik Frost's flyer from 1903 “If I am in favor of achieving a first-class make of soapy food, save every effort or cost and use only first-class material, I am sure that my production will still win and maintain public confidence, as it has been known so far. The knives are solidly made, have a neat appearance, and are guaranteed to meet all reasonable claims for good craftsmanship. Erik Frost, Mora 1903” translated with Google Translator

A spring hammer, a shank cutter, and a colossal screw press helped him make long series of standard-sized parts. He knew that the only way to make the company grow was via large batches and standardization, and this could only archive via industrialization on large scale.

With the help of new and modern machines, Frost truly implemented industrialization and perfected the process of creating the laminated steel (hard steel edge with soft steel side) that was getting so much interest from the clients.

In the beginning, only 3 models were made (see 1903 invoice), N1, N2, and N3.

Erik Frost changed the name of the company to Frosts Knivfabrik AB around 1904?. To dedicate the company exclusively to the knife business.

Above: the year 1904, Erik Frost is in the middle. In 1904, Erik Frost had ten men employed depending on demand and season. 19,000 knives were made in a year and the price of a knife was 80 or 100 öre (1 SEK) per knife with a sheath, slightly more than a normal hourly wage for a worker. In 1911 Pricelist an N.1 would cost 0,35 öre to the retailer.

Earlier on, Erik Frost understood that for him to be successful, he would need partners to help him grow and take care of certain parts of the business, so he could focus on making the knives.

One of his first strategic partnerships was the saddle maker Anders Ström that would make the sheaths for his knives.

Anders Ström helped Erik Frost start the knife factory. In the book, “Ströms Knivslidfabrik. En dokumentation av Annica Kjellson 1995” is mentioned, “Someone has said that Östnor's industry would not have been what it is today if Ström had not helped them.” More info https://oldmora.blogspot.com/2022/05/AndersStrom-and-Unicasheath.html

First, he did leather sheath since 1904 and the UNIVA fiber sheath around 1907 or 1908?

In this post on Facebook group "Du vet att du är från Mora när" https://www.facebook.com/permalink.php?story_fbid=1672842052777391&id=228565797205031 Owe Hållmarker mentioned a story contained in a booklet about Duvmyren by Bengt Ström in Östnor written by Anders Norén. Duvmyren is located near Östnorsfäboden Kansbol, where Erik Frost and Erik Böhlmark challenged Anders Ström to make sheaths for their knives. The date of this event is unknown but I suppose it must have taken place in early 1905.

“On Sunday, the knife-fabricator Erik Frost and the wholesaler Erik Böhlmark came up and greeted. They wanted Anders to make sheaths for Frost's knives. But Anders said he was " wir era arbetär ", tired of that work. But the seed in the head of the technically gifted and handy shoemaker' which led to the development of the fiber sheath UNICA, as well as tools and working methods needed for profitable manufacturing on an industrial scale.

In 1908 Erik Frost filled a patent from the knife sheath with the very distinctive hood. This model was called fäbod-kniv and was common in the Dalarna and Hälsingland regions even before Erik Frost's time, despite this, he managed to get the patent approved.

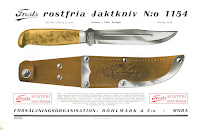

Above: 1911 Pricelist. Price per unit goes from 1,17 SEK to 1,33 SEK

In the 1911 catalog, an introduction for these models is stated.

“…With these sheaths there is always the risk that the knife will come loose, come out of the sheath, and be lost. These disadvantages are eliminated by the present invention. according to which the sheath is provided with a lid which is displaceable on the strap serving to attach the sheath and is slid onto the knife shaft … By means of this device the lid can never be shaken or by the person carrying the knife, leaning or otherwise leaving the shaft, but the lid can only be removed by hand. As a result, the knife can sit completely loose in the sheath, without there being any risk of the knife falling out of it. Said abutment also serves to prevent the lid from leaving the strap, if it is simple (not loop-shaped). The insertion of the knife, as well as removal, can be done easily and conveniently and without the risk of the knife cutting the sheath. Due to the suspension of the sheath in the strap, the sheath with the knife is always with the flat side against the wearer's body, which is an advantage. “

Another partnership would be with Böhlmark & Co https://oldmora.blogspot.com/2021/05/BohlmarkCo.html, with who Erik signed a contract for the sales and distribution of the knives, in 1910. Erik Frost's main focus would be on making the best product possible and Erik Böhlmark would become a general agent of Frost, dealing with marketing, sales, and distribution.

From the 1911 Frost / Böhlmark & C catalog. Google Translator: “The manufacturer E. Frost in Mora has handed over to us the entire sale of its well-known manufacture of knives and sheaths.

To the extent that we hereby have the honor to submit an illustrated complete price list of this production, we ask you to include yourself in a prone memory in case of need.

We point out that the reason for the good judgment about Frost's make is to look for the good condition of the edge as well as for the tasteful appearance of the whole knife. Namely, the knives are forged with inlaid steel, whereby their value as an edge is significantly increased.

To be able to provide as faithful a picture of the knives as possible in the price list, the illustrations have been made in life-size, except No. 3, Jaktkniven, and Späntkniven.

On the other hand, prices included in this price list, which are net for retailers, are granted a 10% discount when buying at least 50 dozen at a time. For larger parties discount according to special agreement.

Mora in January 1911.

Böhlmark & C: o.”

One curiosity, when Böhlmark & Co made a similar distribution contract with KJE, Erik Böhlmark stipulates that the price he would pay to KJE was indexed to the price of a similar knife model that E.Frost sold. This already shows the importance of the company in the knife business in Mora.

In the 1911 pricelist, the number of models grows exponentially: Classic line: 2/0, 1/0, 1, 2, 3 with or without a sheath or with the hooded sheath (only 2/0, 1/0, 1); The wood handle also could be the regular red handle or for an extra cost could be curly birch; Exclusive line: 10, 11, 12 and 13

Link to the catalog https://drive.google.com/drive/folders/1KU0EwTSsJiJM26HJX1iu4o91FZyDIPJl

Above, a set of Böhlmark & Co seller cases, owned by an Eric Grudin who had a shop in Mora where he sold large quantities of knives, mainly to tourists during the 1960s and on Erik death were passed to Ola Grudin (Eric Son). These cases were called “test rider bags”, as the merchants/sellers were called, and they took the bags out to stores where they sold in bulk. These suitcases contain knives that are glued aboard. There have three draws in each case and each plane is untouched knives The collection is from the 1920s, When Böhlmark & CO's closed in 1962, Erik bought parts of the stock of Frost's knives and started a tourist shop in the old Östbygge HAB's premises on Strandgatan called Kniv-Expo. Eric also managed to buy a stock of FM Matsson's exclusive hunting dagger(ref: Source: Knivmakaren 2005 nr 3 ) These cases were auctioned in 2017 and the collection of Morakniv. More info here http://www.cultur.nu/knivar/mora/moramapp_2017/moramapp2017.htm.

Above: Image from the article Knivmakaren 2006 nr 4 Mora-Nisse och Moraknivarna date from the 1910s

In 1911, he filed a patent request from a special retention system. A type of lash on the sheath that would engage on a grove on the handle of the knife, preventing the knife from getting of the sheath

The sheath was fabricated by Strom but the final assembly was probably made in the Frost factory.

Although an ingenious design, this sheath was sold only for a relatively short time.

In the early 1910s, KJE worked for a brief period at Frosts Knivfabrik but after a discussion with Erik Frost, he was kicked out of the factory. Read everything here https://oldmora.blogspot.com/2020/12/kjeriksson.html

In 1916 electricity reached Östnor that would benefit the industry.

Another important factor to the development of the business and all areas was the arrival of the train to Mora https://en.wikipedia.org/wiki/Inland_Line

In the 1920s, Frost had already eight trip hammers and produced more than twenty different models. Frost now employees more than 30 men.

Above: 1926 - Front row: Karl Morell, Emil Dahlberg, Sol-Oskar Andersson, Bogg-Oscar Eriksson, Anders Frost (Selja), Klas Eriksson, Göte Brask (the little boy), Frost-Anders Karlsson, Ivar Frost, Edvin Hennocks, Johan Frost, Lars-Anders Eriksson (Wit) jr. Mid row: Flint-Lars Andersson, Anders Dahlberg jr, Anders Dahlberg sr, Anders Sisell, Gard-Viktor Karlsson, Anders Lund, Lars-Anders Eriksson (Wit), Bond-Anders Frost, Karl Frost, Sven Frost sr. Back row: Erik Finns, Helmer Morén, Frost-Karl Karlsson, Karl Persson, Tåmås-Karl Andersson, Bror Selling, Ernst Eriksson.

Frost Erik Eriksson – Data unknow

In 1924-12-20 Frost Erik Eriksson died at age 59. His son Karl Frost (https://www.morahembygd.se/wp-content/stigsson/pfd2a4188.html) assumes the leadership of the company.

Karl Frost – Date 1942 1942-02-28 Såningsmannen (Hur Morakniven blev en världsartikel)

All Erik Frost worked at the factory.

In the mid-1910s the word “Sweden” starts to appear in the stamps of the knives due to increasing exports.

Frost would also make and sell loose handles, ferrules, and blades in batches to other makers in the regions like Bud-Carl Andersson, Krång-Johan Eriksson, Jöns Persson, Frost-Mats Mattsson, and Finn-Anders. Virtually all knife makers in Mora, have at some point worked on or bought parts from Erik or even stamped their name in blanks made by Frost. Source: 1992-nr-5-Antik-Auktion.

In time, the classic line reaches 10 different sizes.

Wit-Anders Ersson worked at Frost in the 1920s and 1930s. He was a recognized skilled knife manufacturer. On his own initiative, he made a series of knives that were so appreciated that they were taken by Frosts into production in a series of 5 knife sizes, with and without a guard. Read the full history here https://oldmora.blogspot.com/2020/08/wit-lars-anders-eriksson-1878-1945.html

Ref: http://thebladeblog-ulf.blogspot.com/2015/11/famous-cutlery-from-sweden-mora-knife.html

Photo from the article 1992, nr 5 Antik & Auktion, show the exclusive models from 1920-1930

According to Larsson (1992), the Erik Frost factory at the pick of the hand forge inhouse had 8 industrial forging hammers and more than 30 workers during the 1920s and 1930s. Not only was Frost-Erik able to produce the same quality of the early hand-forged blades using machines, but he was also able to improve the production of standardized parts.

Above: Crow Karl Persson "Peres Karl" sharpens knives. Päres-Karl in the picture has a wooden stick as extra support The picture was taken sometime in the 1930s. Source: Antique & Auction 1992

Frost displays, age unknown but probably the 30's

In 1931, a new brick building/workshop was at the same place as the original one.

Sellers wood briefcase. Data unknown

Another knife maker that learned the trade at Frost was Flint-Lars Andersson in the final 1920s beginning of 1930s. Read more about this maker here https://oldmora.blogspot.com/2021/10/FlintLars-Andersson.html

Above: Flint-Lars Andersson, taken from the group picture dated 1929 shown before

In 1935 BÖHLMABK & Co patented the Skidkniv. The main purpose of this knife was to adjust the bindings used in those days and to scrape snow and ice from the skies.

Frost produced the knife for many years in 2 sizes 1102 and 1114. Production ended in the 1950s.

Read the full article about this model

Part of the pricelist 1935

In 1930 Frost employs more than 50 persons. The factory produces at least 150 dozen knives daily in over a hundred different models. It is approaching 1 million knives a year. The cheapest can be manufactured for 50 Öre. while some selected types can cost SEK 7 to 8. Specially made up to SEK 15 and 20. Ref: ( Ref: Hela världen skär med moraknivar Mora Tidning 21-12-1938).

Frost display- date 1940-the 1950s

“He became a leader in the field, and now Erik Frost's knife factory employs over 50 workers. The factory produces at least 150 dozen knives daily in over a hundred different models, from all over the east at least 225 dozen a day. It is approaching 1 million a year. The cheapest can be manufactured for 50 Öre. while some selected types can cost SEK 7 to 8, yes. specially made up to SEK 15 and 20. Through the wholesale company Böhlmark & C: oi Morastrnnd, sales take place practically all over the world. About half of the production is exported, some very weak. e.g. to Argentina. Columbia etc.“ Source Hela världen skär med moraknivar Mora Tidning 21/12/1938

During the Second World War, the export was given a boost and production also included knives for butchers and fishermen.

Knife blades grinding stand around 1940-the 1950s

In 1942-02-28 Såningsmannen (Hur Morakniven blev en världsartikel) article.

“Repairs are currently underway and almost the entire workforce is laid off. The boss himself, Mr. Frost, who took over old Erik Frost's factories after his death in 1924, is found in one of the premises, where he oversees in detail 14 restoration work, and he is not at all reluctant to show the factory.

The factory is by no means modern in that all possible machines occupy most of the spaces. Of course, there are machines of various kinds, but you can see, however, that the main work is done by hand. The handicraft character has not killed mass production. Fifty men are constantly at work, and the annual production amounts to tens of thousands of knives. "But how on earth can the Swedish people need such lots of vagina knives?" "Firstly, we make not only sheath knives, but also cutters, butcher knives, etc. Secondly, a very large percentage of the cost is exported. Thus, we have sent huge boxes of knives to Japan. Manufacturing has certainly reached an astonishing scale." "What do you think it's all about?" "It's all about quality," says Mr. Frost modestly. Maybe on the quality! There's probably the rich answer. Knivsmedernæ in Mora has understood that the thousand dozens of people care as the single knife. And then a world article has come to a small unknown village in Mora.”

Like any other manufacturer at the time, Frost included the scout in their catalog. Many variations were made thru the years, wood handles, plastic handles, false leather, etc

Above: Different scout knives from different eras

On a cold winter night in 1947, more precise on a Thursday 27/2/1947. A fire destroyed the Frost factory. Firefighting was not facilitated by the fact that it was -30 ° C cold outside. The wall of the 1931 brick workshop building was intact but the roof collapsed.

In the local journal the incident made the headline, “Frost's knife factory fired in the cold Downtime and damage for more than 100.000 SEK at the time.”

In the news, it is said that the fire was first seen at 3 am but no alarm was raised because it was thought it was a soot fire but soon the firefighters were called. In an hour, the fire destroyed all the upper floor where the grind rood, carpentry, and warehouse were located, before the firefighters control de fire. The machines on the ground floor only sustain damage by the water. A large number of knives, that were waiting for shipment, was consumed by the fire. They suspect the fire started in the electric system.

It's unknown how much time did they stop.

Mora newspaper article about the fire. "downtime and damages for more than 100,000 SEK"

Translation: "NOTE! If there is a need for improvement or sharpening of the edge when using Frost's stainless steel knives, it should be observed that the knives must not be sharpened on coarsely grooved sharp steels, but should preferably be sharpened on fine sandstone and then sharpened on a suitable oil sharpener. In most cases, an oil sharpener of suitable quality should be sufficient to maintain the good sharpness of the knife. The high-quality special material in these knives requires special sharpening care and must not be treated as knives of other lower steel qualities. ERIK FROST'S KNIFE FACTORY - MORA"

Erik Frost 1946 Svenska Journalen Nr 16 1946

From the 1930s (or even a few years earlier) inward, all Mora manufacturers started changing from laminated steel made in-house to pre-rolled laminated steel WH101 made by the Swedish mill Vikmanshyttan (that began producing laminated steel in 1923).

Now all the knives are stamped and not forged like back in the day. An article from 1946 already says that all laminated steel is brought by train to the company “Now the steel and iron are not joined together by hand. In long bands, the raw material comes from the railway to be punched out by Frost's skilled workers into knife blanks. Everything is largely mechanized, and at a speed of about 120 dozen a day and this forms a significant part of Mora's entire knife production”

In the late 1950s, the last spring hammers would be phased out. Also in the 1950s, the WH101 is discontinued. Frost starts buying from European suppliers, first from Germany and then France.

Above: Stamping station, Frost Catalog 1960

1948 Directions for tourists (Mora)

Although Frost was prohibited to sell their knives with Frost stamp because of the Böhlmark & Co contract, they sold the same knives with a different stamp for special contracts identifying just “Mora made in Sweden”

In 1953, during the visit of GUSTAV VI to Mora, Böhlmark & Co delivered a copy of the famous Zorn knife made by Frost company.

The knife was made in the Frosts Kniv's factory by Oskar Frost (1918-67 – not related to the owners), that was renowned for his technical talent. The knife took 5 weeks to be made (most of the time was spent making the sheath) and was completely done by hand. the Zorn Museum landed one of the famous knives to be used as a model.

Photos from 1953

The upper part of the sheath bears the royal emblem in the place where the original had decoration, the fitting was made out of pure silver

The length of the knife is 235 mm and the length of the sheath is 180 mm. The blade is made of stainless steel as the factory's logo is etched with an electric etching machine.

The knife was given to King Gustav during the royal dinner at Mora Hotel.

Source Article in Dala-Demokraten on September 12, 1953

More info about the magnificent Zorn knives here http://www.cultur.nu/knivar/expo/knivmuseum/zorn/

The contract with Böhlmark & Co ends in the 1950s and marks the end of the more than half-century partnership.

The 1950 and 1960 see the born or of the very popular models:

4111 in stainless and 311 with laminated steel

Kitchen knives

Woodworking knives and spoon knives

344, 345 & 346

In 1960 Frost evaluated the possibility to buy the knife business of FMM but soon realized that the machine park was dated and the models old fashioned and dropped from the business. KJE end up buying the FMM after a backstage move. Read all about were https://oldmora.blogspot.com/2020/01/fm-mattsson-1917-1962.html

Since at least the 1940s Frost was a regular supplier of utility knives for the military. Knives branded Erik Frost and Moraknivfabrik (brand owned by Böhlmark & Co and made by Frost) are common.

Since the 1950s, Frost developed two different survival knives to equip pilots of the air force.

The accident report of a Saab J32 in 1963, in the inventory of the material that the pilot had with him, was an M6310-010010 survival knife. Full report here https://drive.google.com/file/d/1ixaztYqNY18_IrYalAxONQDOYxpCVLZf/view?usp=sharing

Starting from 1980, the classic was substituted by the 700 series in military contracts.

From left: Several different military knife examples, Classic N.2 with black handle, rare 1960 Airforce pilots Survival Knive, Probably a prototype made in Frost workshop, 2 M6310-010010 with a different stamp from the 1970-1980, 700 series utility knife

More info on Morakniv in the military https://oldmora.blogspot.com/2020/02/mora-knifes-in-military.html

In the late 1960s, Carl-Eric Frost (grandson of Erik Frost) became CEO of the company. In the management team were also his brother Göran, his cousin Göte Brask as a factory manager, and brother Anders and Per Brask.

In late 1960 there was a curious occurrence. Frost received several phone calls from clients, complained that the Mora knives came loose from the handles. convinced that the knife was made by Frost knives. The decor of the sheath, the shape, the color, the handle was identical to the Frost knife. But there was no Frost stamp on the knife blade and the reason the blade came loose from the shaft was that the pinning of the tang was too weak. These were knives copies made in Japan, not in Frost.

Carl Erik Frost dies in 1972.

In 1973 Frost had 95 employees and 70% of their production is exported. Ref: 1973 Nr 10 Jaktmarker och Fiskevatten.

Probably from 1970s or 1980s

In around 1973 Frost release the first MoraClassic with a guard, N.201/202, probably already a response to the later science article “Moraknivssyndromet” about the injures that knives without guard do. Check in the study in Swedish

Above: Diferent 201 examples, from diferent eras. From left: the original one with laminated steel, Carbon steel version, 2x UNICA sheath version ( I think they are from the military contracts M6310-004010)

Image from 1976 article Järnhandlaren Nr 2. Carl-Eric Frost shows the different steps in manufacturing a knife, from the raw steel, the stamping of the blank, and the finished knife with a handle.

In 1976 the factory as 90 employees, 250 models, and 10-12,000 knives are manufactured per day.

In the second half of 1970, Frost introduced the S1 craftsmen plastic handle knives. The first plastic handle model from Frost.

In 1985, Frost as produced over 75 million knives of the classic red handle knife, since the beginning ref: 1985 Nr2-3, Jakt & Vapen. 50 percent of the company's total production is the red handle knife, 25% to hunting and fishing and 25 percent of production goes to commercial kitchens, family kitchens, fishing industries, bakeries, and grocery stores.

In the 1920s it was made with a silver sheath and with a shaft in curly birch. That model would cost over SEK 500 to manufacture in the 1980s.

The stainless steel comes to Mora from Sandvik in five meters long rods or large rolls. After the blades have been punched out, they harden in between 850 and 1150 degrees heat. Then it is time for grinding, polishing, and browning.

Despite the industrial handling, some work steps still take place in the same artisanal way as in Erik Frost's time. Part of the grinding is performed on an old-fashioned grindstone. As recently as 15-20 years ago, the manual grinding of the mora knives ceased. Before that, Frost had seven stone grinders employed. A skilled stone sharpener could sharpen 900 knives in one day.

ref: 1985 Nr2-3, Jakt & Vapen.

In 1980 the Viking model was introduced in substitution of the S1. First, with a hollow handle and then solid plastic handles ….

… And the 700 Series 1980s - 2005

One interesting story is told to exemplify that Mora knives have reached all parts of the world, a Swedish sailor was surprised to find a mora knife in a souvenir shop in South America. The clerk explained that Sweden was an island off the South American continent and that Frosts was the name of the chief of the knife-making tribe.

In the late 1980s, Frost stops making their wooden handles in-house and outsource them to an external supplier. ref: 1987-09-16 Mora Tidning

Also in 1980 Frost begins to enter the “computer age” with the introduction of computer systems to control production, warehouse, etc. Robots began to be evaluated in how they could be applied to optimize the production line.

In the spring of 1987, Frost almost fell into the hands of its Finnish competitor, Fiskars, because of internal struggles among the different owner groups. At that moment the company was owned by the Frost and Brask families with 29 percent each, while the remaining 42 percent are among other descendants.

In 1988-06-21 Dala Demokraten newspaper, the article starts with “A power. struggle among the owners of Frost's knife factory threatens its future. There is much to suggest that Mora's largest knife factory dating from the 19th century is being sold to the worst competitor.”

On the other hand, among Frost employees, there was a generalized concern about the company ending up in the hands of KJE and the future of the company.

From the press release of 22.06.1988 “The deal originated in that Fiskars OY AB from Finland showed interest in acquiring Frosts Knivfabrik in the spring of 1987. The business talks eventually led to the company management negotiating a so-called Letter of Intent or preliminary agreement for the sale with the Finnish company in June 1987. When the agreement was to the other shareholders, it was received with great hesitation. On the one hand, it felt strange that such an all-Swedish product as the Mora knife would be manufactured by a foreign company, and on the other hand, there were natural concerns about how the continued development at Frosts Knivfabrik would be after a takeover. Fiskars OY already has production of knives in Finland, Eskilstuna, and the USA. In Eskilstuna, it was known that the subsidiary Knivman had acquired competing companies, which were then closed down”

After the rejection of the Fiskars offer, Per-Erik Frost tried to buy the 42% shares from the "42 percent group" and take full control of the company but the offer was rejected. The group of shareholders wanted FM Mattsson to step in and save the knife company’s position in the village. But FMM had no expertise in the knife business (FMM left the knife business space almost 30 years before) so KJE was called. FMM together with KJE (FMM and KJE owned together, the local hardware store) stepped in and purchased 72% of the capital of Frost, 36% each. (In the KJE book, it says the Brask family have 28%, KJE 36%, and FMM 36%)

The business was concluded in 22.06.88.

Olle Mattsson, Bo Eriksson, and Anders Brask mark the new ownership picture at Frost's knife factory. Also pictured are employees at Frosts and union ombudsman Gösta Frost. Source: book KJ Eriksson 1912-1992. The newspaper article is from the day after the closed deal.

Because of the support and participation by the Frost Family in the Fiskars negotiations, the Frost family left the company, remaining the Brask family in command of the new era of Frost.

In 1988 Anders Brask became the CEO (https://gw.geneanet.org/perslars?lang=sv&p=anders&n=brask) and his brother Pär Brask became the product developer. They are great-grandsons of Erik Frost. Pär Brask still works at Morakniv.

In 1988 Frosts Knivfabrik had about 90 employees.

In an interesting article in a newspaper, Anders and Pär Brask explain the pricing of a knife made by Frost.

A knife cost 40Kr :

Above: Raw material (steel, wood, plastic) SEK 4:25, Salaries at Frost's knife factory SEK 8:00, Social security contributions on these salaries SEK 3:10, Capital costs (machines, buildings) SEK 0:50, advertising and publicity 0:20 SEK

Bellow: VAT 8:00 kr, Retail 9:00 kr, Wholesale 4:50 kr, Shipping from Mora (truck) SEK 0:15, Profit for Frost's knife factory SEK 2:30

Knife costs 12:25 to manufacture (rowan and raw materials), but SEK 40 in the trade. Social taxes, payroll taxes and VAT disturb for 11:10, almost as Wholesale and the 71, sled for the third ton The profit for Frost's iv factory is 2:30.

In 1991, Frosts Knivfabrik celebrated its 100th anniversary and had about 300 different models in its product range. About 60% of these were regularly exported to more than 50 countries, primarily the neighboring Nordic countries, the USA, Canada, South America, and Australia. The traditional Mora knife accounted for about 45% of Frosts Knivfabrik’s production.

Date 1998

In The 1990s 50 % of the production is exported Mainly to the Nordic countries but also the USA, Canada, Australia, Hungary, New Zealand, Australia, Nicaragua, etc

In 2000 Frost produced 200000 knives, 10,000 knives per day. 60% is exported

In 2001, Par Brask in an article 2001-02 Scandinavian Export Magazine, make a very interesting comment about the heat treatment used at Frost at the time "especially when followed by a deep cooling process. The steel is cooled down to minus 80-90 degrees. This increases the hardness by approximately 2 units Rockwell C.". although the heat treatment used was always one the best keep secrets with this comment it safe to say that they used some type of cryogenic knife treatment.

The 2000s see the born of the successful model the Clipper. This would later be slights changed and converted into the Companion that is still in production in 2021

In 2004, KJ Eriksson AB acquired the remaining shares of Frosts Knivfabrik. The first step was taken in 2002 by the acquisition of FM Mattsson’s shares, and the second in 2005 when the Brask brothers sold the rest of their shareholdings. Frosts Knivfabrik became a 100% owned subsidiary of KJ Eriksson AB.

After 2005, the Frost brand continues but only for the food industry and hoof knives. The Frosts brand had gained a very respected position in this segment in the last decades, so the decision was made to keep the brand alive and capitalize it since it had a lot more name and recognition than KJ in this space.

Full current catalog https://morakniv.se/en/knife-series/frosts/?v=35357b9c8fe4

In 2005 the old factory was sold to Östnors Företagspark. https://www.dalademokraten.se/artikel/ostnors-foretagspark-skapas

CEO

Erik Frost 1891 – 1924

Carl Erik Frost 1924 – 72: son of Karl Frost

Per-Eric Frost 1972-1988: son of Carl Eril Frost

Anders Brask – 1988 – 2005 ( descendent of morahembygd.se/wp-content/stigsson/p0a02dfa6.html ?)

Curiosities

Frost Erik Knivfabrik phone number 43

Old Ads

https://www.google.com/maps/place/Landsv%C3%A4gen+11,+792+95+Mora,+Su%C3%A9cia/@61.0259932,14.5027511,19.62z/data=!4m5!3m4!1s0x4667db8d598aa895:0x5dbd2d63285ed93!8m2!3d61.0259561!4d14.5029409

Special thanks

A special word of appreciation to Pär Brask and Thomas Eriksson for all their contribution with documents and validating dates, names etc.

Comments

Post a Comment